Building an LMS Jubilee 4-6-0

One of the remaining Alan Gibson LMS loco kits that I haven't built is the 'Jubilee'. The kit I have is reasonably complete with both smokebox and firebox castings. Missing were some of the castings needed for the cylinders. Also missing were the instructions but luckily, having built several of the Gibson kits I was able to work out where most parts were intended to go. Because of the similarity with the Class 5 kit I'm not describing construction unless i feel there is anything to add.

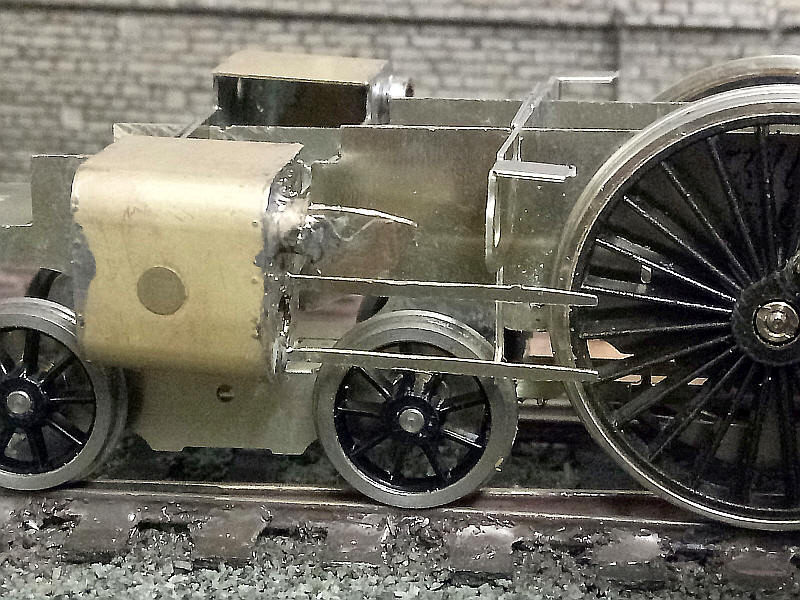

This is the basic chassis, running plate and cab assembly. The wheels are Markits 4mm scale drivers intended for locos with 8 feet diameter wheels which scale out almost correctly for the Jubilee's 6 feet 9 inch diameter wheels although they have 3 spokes too many.

One of the problems I needed to overcome was the absence of castings for the cylinders. I contacted the owners of Alan Gibson but the castings don't seem to be available any longer. The valve stem guide at the top of the cylinders supports the joint between the combination lever and the radius bar.

The white metal casting I've used on the other LMS models was a beautiful casting although potentially easily broken. To make my own I have soldered a short length of 1/8 inch diameter tube to the rear end of the cylinder. A piece of phosphor bronze strip was cut to roughly the correct size and profile and passed through the brass tube and soldered to both it and to the hole at the front of the cylinder. Another strip, this time of nickel silver was soldered through the tube and to the front of the cylinder making sure that there is a gap between the two pieces of metal.

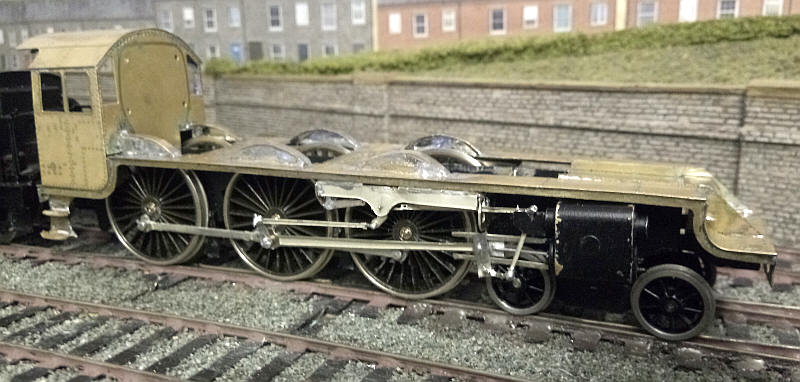

The running gear of the Jubilee is now complete with my usual methods as described in the Class 5 and 8F used to produce the crossheads. Making these doesn't get any easier and I wish I could think of a more elegant solution.

The firebox and boiler substructure are joined together. The firebox is a pewter casting for the long firebox version of the Jubilees. The boiler is from a length of plastic central heating pipe cut lengthways along the bottom and forced out to a larger diameter by inserting four 20 cent (Euro) coins into it. A strip of tube was cut and inserted into the bottom of the "boiler" at the bottom. This was then glued to the front of the firebox casting checking that everything stayed aligned and central.

The taper boiler has been constructed using carefully placed packing strips of card located around the inner tube and then several layers of thin card wrapped around reinforced with epoxy resin.

As with my other locomotives with cardboard boilers I cleaned all the metal parts and primed then before permanently securing the boiler and firebox to the cab and footplate.

The boiler castings sandbox covers and smokebox door have been added. The smokebox door is a photocopy glued to three card discs of different sizes and the secured to the front of the smokebox with epoxy resin. The paper stretches slightly and it can be persuaded to be down without gaps. A coating of superglue further hardens the paper.

The construction of the powered tender and various items on the loco itself means that the jubilee is now ready for the paintshop.

The undercoat blends the various media together and it's beginning to look like a Jubilee.

I've chosen the number 45564 'New South Wales' because the kit came with a set of nameplates and also because 'NSW' was based at Leeds Holbeck shed in the 1950s and 1960s so is an appropriate loco to work the semi-fast services to Skipton and Leeds from Pendle Midland.